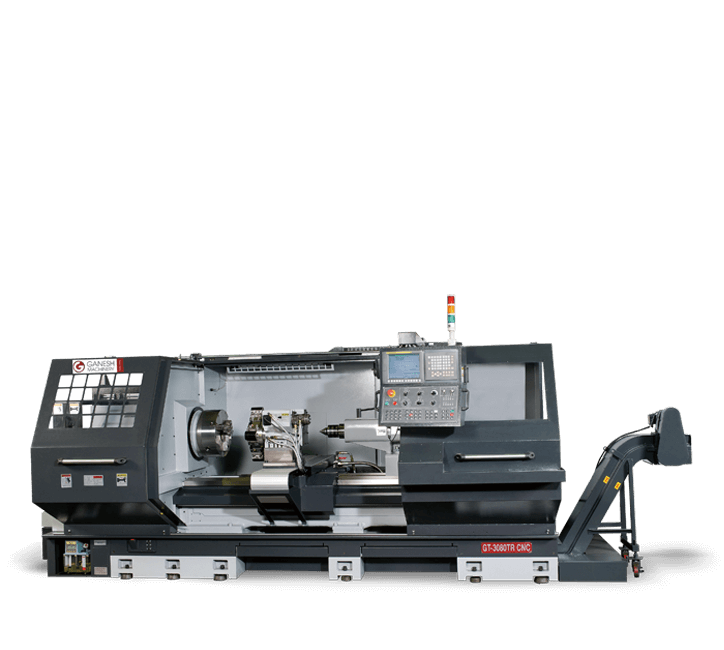

CNC LATHES

GTW-30 CNC

30” HEAVY DUTY CNC BIG BORE LATHE

- LA2-11 Spindle w/ 6-5/8” Bore

- L10 – 1000 RPM Standard

- LA2-15 Spindle w/ 10” Bore, 18 – 600 RPM Optional

- L2-Gear Ranges for Increased Cutting Torque

- L8-Station Tool Turret – Any combination of ID/OD tools

- LDual-Turrets ( Front & Rear of cross slide ) Available

MACHINE SPECIFICATIONS

Capacity & Dimensions

Swing over Bed | 30″ | (760 mm) |

Turning Diameter (in front of cross slide w/8 station turret turning tool | 22″ | (560 mm) |

Swing over Cross-Slide (turning diameter over cross-slide) | 19″ | (480 mm) |

Center Height | 15″ | (380 mm) |

Bed width of ways | 18″ | (460 mm) |

Bed Casing Height | 15.75″ | (400 mm) |

Spindle

Spindle Motor Horsepower (Fanuc 15 Kw – 18 Kw) | 30 HP | (25 HP 30 min rated) |

Spindle Speeds | 10 – 1,000 RPM | |

Spindle Gear Ranges – 2 automatically selected gear ranges | L = 30 – 300 RPM | H = 10 – 1000 RPMS |

Spindle Bore (10″ bore optional) | 6.69″ | (170 mm) |

Spindle Nose (front & rear) / bearing | A2-11 / Taper Roller Bearings | |

Spindle Torque for 6 5/8″ bore – low gear / high gear | 1,180 / 346 ft lbs | (1,600 / 470 Nm) |

Big-Bore Spindle Option – Bore Size | 10″ (255 mm) | A2 – 15 spindle |

Big Bore Spindle Speeds | 18 – 600 RPM in 2 ranges | |

Big Bore Spindle Gear Ranges | Low 18 – 186 RPM | High 60 – 600 RPM |

Big Bore Spindle Torque for 10″ bore – low gear/high gear | 1,475 / 442 ft lbs | (2,000 / 600 Nm) |

Axis

Rapid Traverse Feedrate X & Z | 394 IPM | (10 m / min) |

X-Axis Cross Slide Travel | 19 5/8″ | (500 mm) |

Z-Axis Travel (listed with each bed length) | ||

X-Axis Ballscrew Diameter / Servo Motor Power | 1.25″ (32 mm) | 2.0 HP (1.6 kw) |

Z-Axis Ballscrew Diameter / Servo Motor Power | 2″ (50 mm) | 4.0 HP (2.9 kw) |

X-Axis Thrust | 2,020 lbs | (920 kgf) |

X-Axis Thrust | 3,020 lbs | (1,370 kgf) |

Cross Slide Dimensions W x L | 39″ x 10″ | (1,000 mm x 258 mm) |

Minimum input unit | 0.0001″ | (0.001 mm = 40 millionths) |

Tool Turret

Hydraulic type / LS-200R | ||

Tool stations – any combination of ID / OD tooling / Index time | 8 stations | |

OD Tooling (additional ID & OD tool holders in stock) | 1″ tools w/ 8 tool clamps provided | |

ID Tooling (40mm when specified for metric users) | 4 ID (1.5″ bore) holders provided |

Tailstock

Air-Assisted Manual Positioning – Quill engraved with inch/metric quill graduations | ||

Quill Diameter | 4.92″ | (125 mm) |

Quill Stroke (manual quill advance, hydraulic optional) | 7.87″ | (200 mm) |

Quill Taper | MT-6 | Morse Taper #6 |

Tailstock body set-over adjustment | ±0.4″ | (±1 mm) |

Electrical / Hydraulic / Coolant

Power Requirements – FANUC 0i – TF control, motors & drives | 30 kVA / 220 vac / ±5% | |

Hydraulic Motor Power | 2 HP | |

Hydraulic Pressure | 435 PSI / Mobil #32 oil | |

Coolant Pump | 3/4 HP | |

Machines need stable 220 volts, 3 Phase – Please use appropriate transformers or voltage stabilizers |